Yunohana-goya

and Manufacturing Process

Yunohana-goya created by craftsmen by hand

Yunohana-goya created by craftsmen by hand

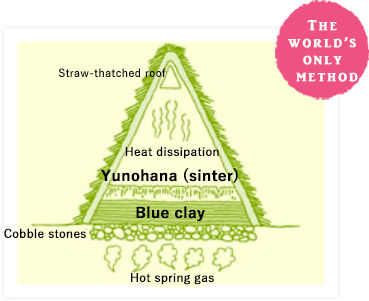

The Myoban Onsen region is geothermal. Hot spring veins exist at a depth of only 30 centimeters below the ground level and hot spring gas vigorously blows out from the ground surface. Huts with a straw-thatched roof standing in this region are yunohana-goya, or sinter producing huts, which have been used since the Edo period.

Yunohana Medicinal Sinter, a specialty of Myoban Onsen, is produced by the world’s only method using these huts. This powder is fundamentally different in quality from powdery sulfur produced in other hot spring regions, and this manufacturing method is found nowhere else in the world but here.

Now, how is our sinter produced?

The process starts with selecting a place to build a yunohana-goya; the optimal place is an area with plenty of hot spring steam. Then, stone pavement is created with cobble stones to let the hot spring gas blow out from the ground surface evenly in the hut, and blue clay (scientific name: montmorillonite) which is peculiar to this region is spread out over the pavement. Finally, a hut with a straw-thatched triangular roof is built on it. Steam from the underground gas seeps out through the gaps of the cobble stones into the blue clay, and components from the gas and the blue clay become crystalized. This crystalized material is sinter, which is called yunohana in Japanese. It grows one millimeter a day until collected for 40 to 60 days. It is then dried and made into a commercial product.

Yunohana-goya, which look like dwellings from the Jomon period, have many advantages: they keep the temperature inside stable even on rainy days, do not cause leakage of rain, and their straw-thatched roof emits moisture in the steam out of the hut so water drops will not form. These huts, which were created by the craftsmen with hard labor, only last for three years at the longest because of the action of the steam. The roof is rethatched in that time cycle. Born from extensive knowledge and experience of people in the old days, yunohana-goya can be referred to as the “modern chemical factories in the Edo period.”

Form the frame of a triangular roof with wood and bamboo

Weave bamboo

Complete the roof of wood and bamboo

Thatch the roof with straw

Weave straw with a needle-like tool made of bamboo to make the roof strong

Put straw on the roof evenly

Yunohana-goya that keeps the temperature of hot spring steam at a uniform level

Yunohana-goya completed

Spread blue clay

Work done by hand by skilled craftsmen in the hot steam

Sinter growing one millimeter a day

Sinter all over the inside of the yunohana-goya

Collected after two to three months and then dried

Sinter looking like snow flakes

Dried and dispensed into small bags